Because of its high strength, transparency, incredible heat resistance and dimensional stability, polycarbonate is one of the most popular engineering thermoplastics for new applications.

Polycarbonate is a thermoplastic polymer obtained from carbonic acid. Polycarbonates belong, with many distinctions, to the polyester resins. The most important one is the one derived from bisphenol-A.

The DIN 7728 and 16780 designation for polycarbonate is ‘PC’.

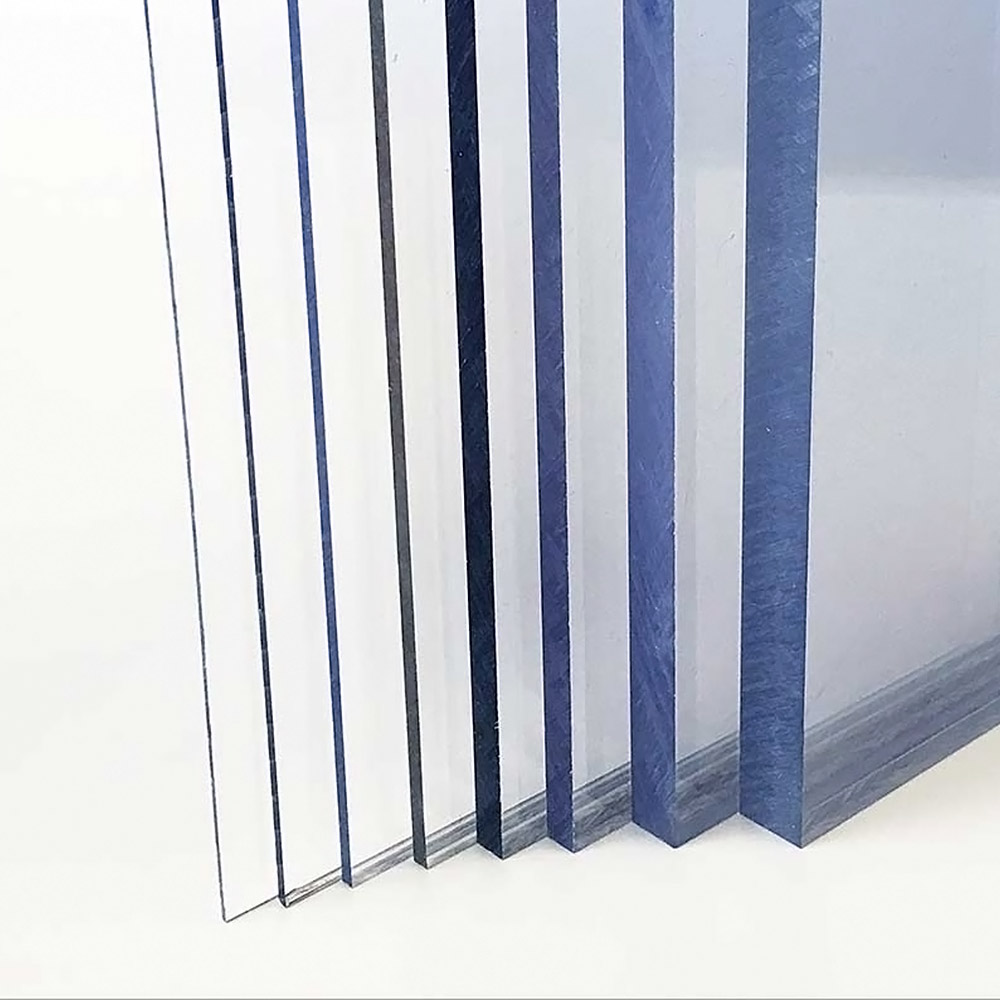

The versatility of polycarbonate makes it an excellent product for creating functional and, at the same time, aesthetically pleasing products. It can be easily moulded and dyed in hundreds of colours – for products ranging from car mirror housings to mobile phone covers to microwave containers. Still, it can also be perfectly transparent, making it the ideal solution for applications such as glazing and skylights.

Transparency, excellent strength, thermal stability and good dimensional stability make polycarbonate (PC) one of the most widely used engineering thermoplastics. Compact discs, riot shields, vandal-proof glazing, baby bottles, electrical components, safety helmets and car headlight lenses are all typical PC applications.

Polycarbonate remains one of the most popular engineering thermoplastics for new applications; the global demand for PC exceeds 1.5 million tonnes.

Polycarbonate is a solid and versatile plastic suitable for various applications ranging from bulletproof windows to compact discs (CDs). The main advantage of polycarbonate over other types of plastic is its unbeatable strength combined with extraordinary lightness. The bulletproof windows and doors often found in banks are often made of polycarbonate.

The most extensive application of the PC is in the optical media market (i.e., the production of computers and audio compact discs). This is followed by a variety of applications such as coating and glazing. The rest of the market concerns electrical and electronic components (hosting applications in telecommunications and office machinery), followed by the transport sector (including automotive), domestic appliances, packaging and other miscellaneous uses.

Some typical uses include:

On-time delivery of processed material is expected within 3-4 weeks after your order. We deliver worldwide.

We can handle your emergencies according to the production time needed for the part you require.

To receive your quote as quickly as possible use the online quote request. Get your quote.